Power tools with brushless motors have become extremely popular in recent years, catching up to the more traditional brushed types. That’s because the tools with brushless motors, like cordless drills, tend to be more efficient and run cooler. They also last longer with little need for maintenance.

Are brushless tools actually better, though? Not necessarily. Many brushed tools might be a better fit for lighter projects.

Read on to learn about the difference between brushed and brushless motors, the advantage of brushless motors, and what is a brushless motor. We also cover the questions you should ask yourself when choosing between a brushless versus brushed motor.

Brushed vs. Brushless Power Tools: Definitions

Brushed tools use carbon brushes to deliver electricity to rotating electromagnetic coils. Because these brushes spin while working and are in constant contact with slip rings, they can create a lot of friction.

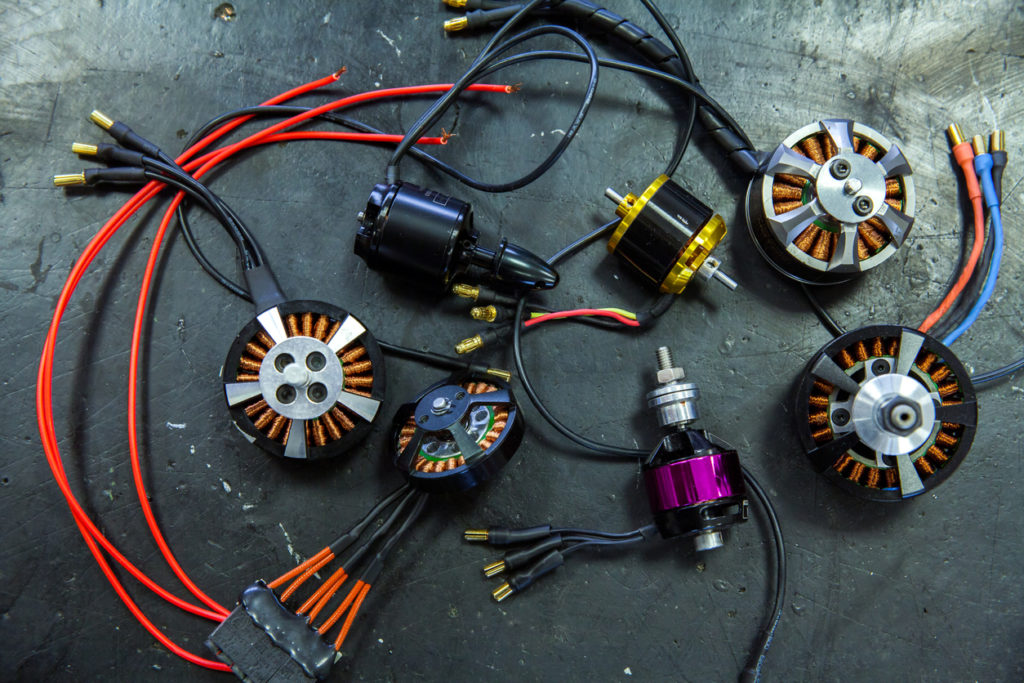

By contrast, brushless tools don’t have brushes. Instead, they use magnets and a complex electronic system to generate power.

Advantages of Brushless vs. Brushed Motors

Each tool type has its advantages and disadvantages depending on the kind of work your project requires. Here are a few of the major differences we found.

Brushless Models Have Less Friction and More Power

Unlike a brushed motor, which creates a lot of friction, the brushless kind produces less of it because they don’t use brushes to transmit electricity. Friction leads to energy loss. Because brushless motors don’t generate friction, they’re more energy-efficient and are more powerful than their brushed counterparts.

Brushless Motors Have a Longer Battery Life

Brushless motors don’t lose energy to friction, resulting in a longer battery life. Many models can run for hours on end, enabling you to work on your projects without downtime.

Aside from having a longer battery life, brushless motors also:

- Require Less Maintenance. Brushless motor tools last longer because there aren’t any brushes to replace. By contrast, brushed motor power tools often require you to buy new replacement brushes because the friction causes the soft brush material to quickly wear down.

- Are Quieter. Brushless motor power tools produce less noise than brushed ones, making them great for quiet working environments. Certain tools, like circular saws, routers, and drills are extremely loud, so if you don’t want to wear earmuffs or make noise while working on your projects, consider getting brushless versions of these tools.

Brushed Motor Tools Are Affordable and an Ideal Solution for Simple Jobs

Although brushless tools offer more benefits, brushed tools may be a better choice for certain projects. Most brushless tools are in the general use or heavy-duty categories, making them unsuitable for light DIY projects like crafting.

There are many brushed motor tools specifically made for DIY projects, though, including brushed drills. So if you want a tool to create something simple, like a candle holder or bird feeder, you might want to consider buying a brushed power tool.

Key Differences Between a Brushless and Brushed Type of Motor

Brushless and brushed power tools operate differently because of their motors. Here are the key differences we found between these two motor types.

A Lack of Brushes

The key difference between a brushless and brushed type of motor is the presence of brushes, which are vital for the proper functioning of jackhammers, hedge trimmers, grinders, and drills.

To create torque, for example, the rotor needs to spin. Brushed motors create torque by using a sliding electrical switch, which consists of a commutator and fixed carbon brushes. These brushes are installed on the fixed section of the motor to transmit optimal power to the rotor. As the rotor spins, brushes are in constant contact with graphite slip rings, creating friction — and that can deplete power.

Brushless motors, by contrast, don’t use brushes to deliver electromagnetic currents. Instead of using brushes and mechanical commutators, they use magnets and electrical systems to generate power.

Price Difference

Brushless motors are typically 30% more expensive than brushed ones. Manufacturers need to manually install complex electrical systems inside the stator due to restricted space. This is a time-consuming and challenging job, which is why manufacturers sell these motors for higher prices.

Choosing a Brushed or Brushless Motor: Which Is Better for You?

To determine which type of power tool is better for you, you need a good sense of what your project involves. Ask yourself:

- What percentage of my projects are heavy-duty jobs, requiring complex control and high performance? Heavy-duty jobs include home improvement projects that involve circular saws, grinders, and table saws. Projects that require cutting metal are also generally heavy-duty.

- What percentage of my projects are light-duty jobs that don’t require high performance? Examples of light-duty jobs include crafting — like building miniature models or creating decorations — and assembling furniture.

If you tackle heavy-duty jobs and tasks frequently, you should consider using a brushless motor power tool. Brushless motors are more powerful, have longer battery life, and require less maintenance. They’re also less noisy, making them perfect for quiet environments and workplaces like your apartment.

A brushed motor power tool might be a better choice, though, if you only work on light DIY projects that don’t require much power. For example, if you only need to build a desk, a brushed drill should do the trick. Because you’re using it for a simple project that doesn’t require much power, you won’t notice the difference. The power difference between brushless and brushed motors only becomes clear if and when you work on complex projects.

Brushed motor power tools are also more budget-friendly, so if you have a limited budget and you don’t do heavy-duty work, consider buying a brushed motor power tool.

Check out our posts of brushed and brushless motor power tools.

- Compact (7.6 in. front to back), lightweight design fits into tight areas

- Ergonomic comfort grip provides ideal balance and tool control

- Bright LED with 20-second trigger release delay provides increased visibility in dark or confined spaces

- Variable speed trigger allows for control and precision on delicate work surfaces

- Bright LED with 20 second trigger delay for working in dark or confined spaces.

- Brushless Motor delivers the power to complete the widest range of applications of any hammer drill driver

- Brushless motor delivers unmatched power for full range of capability to complete the widest variety of applications

- Increase productivity on the jobsite with the fastest driving speed of any impact driver without sacrificing power or control

- Fastest Drilling and Driving applications under load

- Mechanical Clutch for consistency in driving a wide range of fasteners

- The 3-speed selector of DEWALT 20V tools allows users to choose their speed setting based on application.

- Brushless motor of DEWALT oscillating tool delivers up to 57% more run time over brushed

- Dual-Grip variable speed trigger of DEWALT cordless tools gives users ultimate speed and application control

- Universal accessory adaptor for use with most oscillating tool accessory brands

- Quick-Change accessory system allows blades and attachments to be changed quickly without wrenches